==========================================================

• Changed Features in R12 Inventory

----o OPM Inventory conversion.

----o Material traceability: Enhanced material control

----o Dual UOM functionality.

----o Material Status control.

----o Advanced Lot control.

----o Lot indivisibility functionality.

----o Material aging workflow.

• OPM Inventory Convergence

----o Structural changes in Inventory Organization

----o Benefits of OPM Inventory convergence

• Changed features for Inventory Process Convergence

----o Oracle Process Inventory Obsolescence

----o OPM Functionalities are supported by Oracle Inventory

----o New features pertaining to OPM

-------- Dual unit of Measure control

-------- Material status control

-------- Advanced Lot Control

-------- Support for Indivisible lot

-------- Material Aging workflow.

• Oracle Process Inventory Obsolescence: Before

• Oracle Process Inventory Obsolescence: After

• Advantages: Oracle Process Inventory Obsolesces

----o Single Item Master to be maintained.

-------- Process Attributes are added to Item definition

-------- Dual quantity tracking for item.

----o Combined view of Inventory

-------- On-Hand balance in one application

-------- Inventory transacted by one system

----o Integrated Supply Chain

-------- Seamless integration to other products like WMS & MSCA available to Process users.

• Advantages: Oracle Process Inventory Obsolesces

----o Dual Units of Measure control

----o Material Status control

----o Advanced Lot control

----o Lot Indivisibility

----o Material Aging Workflow

• Inventory tracking in Dual Units of Measure

----o Explanation

----o Set up and Process

----o Dependencies and Interactions.

----o Even without constant conversion, quantity can be tracked in two Units of Measures.

----o Transact, reserve, check on-hand and availability in multiple Units of Measure.

----o For Planning and Costing, Primary Units of Measure is used.

• Dual Units of Measure: Set up

----o Define Tracking for Single or Dual UOMs Specify defaulting logic for secondary UOM

• Dual Units of Measure control:

----o Transaction Enter Secondary Quantity at Receipt and all subsequent transactions

• Dual Units of Measure control: On-Hand material

----o View on hand and availability in both UOMs

• Dual Units of Measure control: Dependencies and Interactions

----o Oracle Receiving, Shipping Execution, Order Management, Inventory, WMS and the process manufacturing modules will honor dual UOM

----o If another module in e-Business suit or third party application posts a transaction to inventory via transaction open interface that does not indicate

the secondary quantity, the default conversion is used.

• Enhanced Material control by Material Statuses

----o Introduction

----o Set up and processes

----o Dependencies and Interactions

----o Material Status

-------- List of Allowed and Disallowed transactions

-------- Determination of whether or not the product is nettable, Reservable & ATP-able.

----o Applied to Lot, Serial, Sub inventory & Locator

-------- Assigned at receipt of new lot or serial

-------- Assigned in Sub inventory and Locator forms

-------- Disallowed transactions and planning actions are cumulative

-------- Location status applies to material in location and not Location

----o Update status in material workbench or mobile status update forms

----o Status change history report

----o View On-Hand balances by Material status.

• Set up required to enable Material Status:

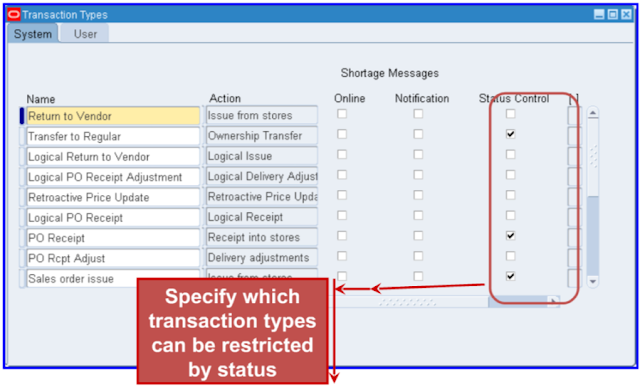

• Material Status control setup: Enable Transaction

----o Specify which transaction types can be restricted by status

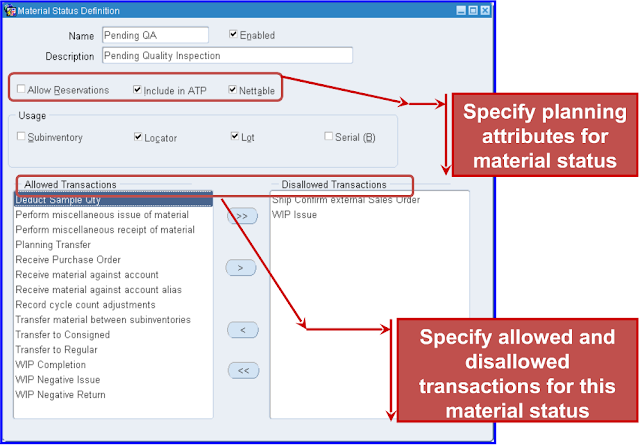

• Material Status control setup: Define Status code

----o Specify planning attributes for material status Specify allowed and disallowed transactions for this material status

• Material Status control setup: Enable Item

----o Enable status control selectively for Items

• Material Status Control Process- Perform Transaction

----o Status restrictions enforced during transactions

-------- Transactions prohibited by status at any level will not be allowed.

-------- Material will not be allocated for transaction not allowed to complete.

• Material Status Control: Dependencies and Interactions

----o Oracle Receiving, Shipping Execution, Advanced Planning and Scheduling, Inventory and Process manufacturing modules will honor material status.

----o If another module in e-Business suit or third party application posts transaction to inventory via transaction open interface that violated material status restriction, that transaction will be allowed.

• Improved Lot Traceability

----o Additional Lot attributes

-------- Grade, Origination, Retest Date, Expiration Action Code, Expiration Action Date, Maturity Date, Hold Release Date.

----o Sub-Lot tracking

----o Lot-level UOM conversions

----o Indivisibility of Lots

• Additional Lot Attributes:

----o Grade, Origination, Retest Date, Expiration Action Code, Expiration Action Date, Maturity Date, Hold Release Date.

----o Grade attributes allowed for allocating a particular grade of material for specific customer or order.

----o Expiration action code allows for particular action to be taken on material when lot has expired.

• Sub-Lot tracking:

----o Sub-Lot: A lot with parent

----o Sub-Lot numbers & Parent numbers can be generated at receipt.

----o Search for material by Lot or Sub-Lot.

----o Automatically name lots as a concatenation of parent lot and sub-lot name.

• Sub-Lot Track: Set up

----o Enable Sublot Control on Item Master

• Sub-Lot track: process

----o Parent Lot number entered during transaction for sublot controlled Items

• Lot level UOM Conversion:

----o Conversions can be created or modified for specific lots

----o Lot level conversions automatically stored as a part of initial receipt transactions for item.

----o Update conversion for the lot and automatically adjust on-hand balances accordingly.

----o View lot level conversions in lot maintenance form

• Lots Indivisibility:

----o Need for Lot Indivisibility

----o Item attribute to determine Indivisibility

----o System will over or under allocate accordingly so that only full lots are chosen

----o Indivisible lots may be manually split, but other transactions for partial quantities are prevented

-------- Exception for receipt into same locator and miscellaneous issue

• Lot Indivisibility: Set up

----o ‘ Lot Divisible’ flag indicates whether lots of this Item can be divided

• Management of Aging of Material

----o Material aging workflow: allows user to be notified about specific date attributes of lot or serial.

----o Concurrent Request: Designed to take action on any date attributes.

-------- The date attributes usually are Expiration date, retest date, maturity date or other types of dates.

----o Workflow is initiated when the given date attribute is within the given number of days of current date defined in concurrent request.

----o Default workflow sends notification, but can be customized to support any functionality.

• Lot Genealogy Enhancement:

----o The enhancement is incorporated in the lot genealogy form to allow user to:

-------- Highlight a particular item lot on a genealogy tree

-------- Toggle between the tabs like ‘where used’ & ‘source’ using highlighted item lot as a top node in the tree.

-------- Refresh the tree with different top level nodes without being forced to go back to query window

-------- View more level of details in the left side navigator where lot branches are expanded before they are forced to scroll horizontally.

• Summary

----o We have learnt about:

----o OPM inventory conversion

----o Dual UOM functionality

----o Material Status control

----o Advanced Lot control

----o Lot Indivisibility

----o Aging of material

----o Lot Genealogy Enhancement

*NOTE: This article is not completely prepared by me, content is edited and complied after referring various sites