Introduction to Cycle count

Cycle Counting is:

- Performed periodically to ensure accuracy of inventory quantities & values.

- Frequency of counting item may be based on the classification of items.

- Example:

- Class A items shall be counted 4 times a year

- Class B items shall be counted 2 times a year

- Class C items shall be counted once in a year

- A method of taking inventory that does not require the inventory organization to shut down in order to count actual inventory items.

- Oracle Inventory: ABC Codes

- ABC Compiles.

- ABC Classes.

- ABC Assignment Groups.

- Inventory, Vision Operations (USA): Counting > Cycle Counting > Cycle Counts

- Setting up the cycle count parameters and scheduling.

- Printing cycle count requests.

- Performing the item counting.

- Entering actual item counts.

- Resolving inventory discrepancies in the database with Finance department.

- Item classification shall be done (by finance and material dept)

- Frequency of counting shall be decides (by Material dept)

- System setup shall be done (by Material / IT)

- Creating a ABC compile.

- Generating ABC descending value report.

- Defining ABC Classes.

- Defining ABC Assignment Group.

- Associating classes and assignment group.

- Assigning items to classes.

- Updating item assignment.

- Generating the ABC assignment report.

- Login to Oracle.

- Select “Inventory, Vision Operations (USA)”

- Select “ABC COMPILE”.

System Reference

User Responsibilities

The store’s in-charge is responsible for:

The store’s person is responsible for:

Ownership

The

Head of Material’s Department is responsible for ensuring that this

document is necessary, reflects actual practices and supports company

policy.

Prerequisites

Steps for ABC Analysis

1. Create a ABC compile

The

ABC compile ranks all the items in your inventory based upon compile

criteria. This ranking is used to assign classes to your items.

Compile Criterion:

ABC

analysis is done based on the value of consumptions. But initially till

next 6 months from the date of Oracle implementation it will be based

on Stock-in-hand value. Moving ahead it will be shifted to Consumption

base.

| Current on-hand quantity |

Use the current on-hand quantity of inventory. Assign the sequence number by descending quantity.

|

| Current on-hand value | Use the current on-hand quantity of inventory times the cost for the cost type. Assign the sequence number by descending value. |

| Historical usage value | Use the historical usage value (transaction history). This is the sum of the transaction quantities times the unit cost of the transactions for the time period you specify. Assign the sequence number by descending value. |

| Historical usage quantity | Use the historical usage quantity (transaction history) for the time period you specify. Assign the sequence number by descending quantity. |

| Historical number of transactions | Use the historical number of transactions (transaction history) for the time period you specify. A ssign the sequence number by descending number of transactions. |

| Forecasted usage value | Use the forecasted usage value based on the forecast quantity calculated and the cost type you specify. Assign the sequence number by descending value. |

| Forecasted usage quantity | Use the forecasted usage quantity. Assign the sequence number by descending quantity. |

| Previous cycle count adjustment quantity | Use the previous cycle count adjustment quantity. Oracle Inventory sums the value of all cycle count adjustments since the last ABC compile date. Assign the sequence number by descending quantity. |

| Previous cycle count adjustment value | Use the previous cycle count adjustment transaction value. Oracle Inventory sums the value of all cycle count adjustments since the last ABC compile date. Assign the sequence number by descending value. |

| MRP demand usage quantity | Use the MRP demand usage quantity. Oracle Inventory sums the MRP gross requirements for the MRP plan you specify. Assign the sequence number by descending quantity. |

| MRP demand usage value |

Use

the MRP demand usage value. Oracle Inventory sums the MRP gross

requirements for the MRP plan you specify. The value is derived from the

item cost type you choose in the ABC compile form. Assign the sequence

number by descending value.

|

- Select “M1” organization

- Select New button on the form.

- Enter a Unique name for ABC compile.

- Optionally, enter a description of the ABC compile.

- Content Scope

- If you select “Organization” ranking will be done for all the items defined for your current organization even those with zero cost and zero quantity.

- If you select “Subinventory “ ranking will be done for all those items for which you have defined an Item/ Subinventory relationship. In this case you can also select specific subinventory defined in system.

- Valuation Scope

- Ranking must be done at the organization level if you did not select a Subinventory in the Content Scope field. If you only want to include items in a subinventory but you want the ranking to be done based on the organization wide ranking, select “Organization”.

- If you select “Subinventory” than only those quantities which are lying in specified subinventory will be considered. Quantities lying in other then specified subinventory will not be considered.

- Compile Specification

- Criterion

- Cost Type defaulted as per setup, Forecast depends on criterion, i.e. if forecast, must select forecast, Plan Name, From Date and To Date are required for some specific criterion.

- Save your work

- Execute the Compile

- Click the compile button and then a concurrent program will get fired.

- If needed compile results can be printed

- Open output of ‘Compile ABC analysis’ to view Compile Result

Complete “Define ABC Compile” form.

- Verify that compile ABC analysis is completed with a status of Normal.

- Select the ABC descending value report.

- Click the view output button to view output.

- Take Print if required.

Note: As this is in test system we got only 504 items in this compile but in actual we would be much more.

2. Generate ABC descending value report

3. Define ABC Classes

Use

your own terminology to determine what are commonly used as ABC

classes. Define class names that suit your business environment.

Navigation: Inventory, Vision Operations (USA) > ABC Codes > ABC Classes- Enter Class Names and description

- Save your work

- Enter a unique ABC group name.

- Associate Compile Name and save

4. Define ABC Assignment Groups

ABC

assignment groups associate ABC classes with an ABC compile. You assign

item to ABC classes within a particular group. This allows you to

assign items to different ABC classes in different group.

For

example, suppose you define ABC groups “Cycle Counting” and “Planning”. You can define different ABC classes to these two groups.

You can then assign an item to a different ABC class in each group. This

allows you to prioritize item differently for Cycle Counting and

Planning.

Navigation:

Inventory, Vision Operations (USA): ABC Codes > ABC Assignment Groups

Complete the ABC Assignment Groups form. On a blank line fill the following information.

- Choose classes to use with assignment group

- Assign ranking to the classes within an assignment group.

5. Associate Classes and Assignment Groups

ABC Group Class Assignment

- Select your assignment group from the list. Click the Group Class button.

- ABC Group Class Assignment window will get open.

- Complete the ABC Group Class Assignment form.

- Priority: Enter the sequence number in which classes are ordered. Number “1” is the most important, number “2” is second, and so for.

- Select the class names you defined.

- Sequence Number

- Items Percent

- Inventory Value

- Value Percent

- Open ABC Assignment Groups window.

6. Assign Items to Classes

Assignment may be made based upon following criterion.

- Select your assignment group from the list.

- Click the Assign Item button.

- Assign ABC Items window will get open.

As

numbers of items in the compile are very less, here we are taking 50

items in Class A, next 100 items in Class B and rest in Class C.

In real business scenario it might be different, it could be based on the value.

Example:

In real business scenario it might be different, it could be based on the value.

Example:

Top Items having 85% of value is considered as Class A item.

Next Items having 10% of value is considered as Class B item.

And rest of the items would be considered as Class C item.

- Specify the cutoff point for each ABC class. Each ABC class must have at least one item assigned to it, and all items in the ABC compile must be assigned to an ABC class. You can use any of the following fields to determine the cutoff point.

- Assign Item

- Click the Assign button.

- Click the OK button.

- A request is generated, press OK.

- Check the request status.

Sequence: You

can enter the sequence number from the ABC Descending Value Report for

the last item to be included in each ABC class. This value will be

automatically calculated if you choose to assign classes by another

method.

Inventory Value: You

can enter the cumulative value from the ABC Descending Value report for

last item to include in each ABC class. Maximum value is automatically

calculated. This maximum value is restricted to the total inventory

value compiled and displayed in the Total Compiled Value Field.

% Item: You

can enter the percent of number of items compiled from the ABC

Descending Value report to include in each class. This value is

automatically calculated if you choose to assign classes by another

method.

% Value: You

can enter the percent of total compile value from the ABC Descending

Value report to include in each class. This value is automatically

calculated if you choose to assign classes by another method.

Attention:

It is possible to have several items in the ABC compile with Zero

Value. If any item with zero value is in a class other than the last

class, you may only assign item using Sequence

For

the inventory value, % item and % value field, if the value entered

does not exactly match any item, the first item with value greater than

the value entered is taken.

- Go to ABC Assignment Groups window.

- Select your Assignment Group from the list.

- Click the Update Item button if required.

- Update ABC Item Assignment screen will appear.

7. Update Item Assignment (if required)

Find Your ABC Assignment

- To enter a new item assignment.

- Click the New Record button on the toolbar.

- In the blank record, enter the item number and ABC class.

- To edit the class of a specific item.

- Find the item number in the list or use find to search for an item number.

- Use the list of values to select a new class for the item.

- Save your work and close the window.

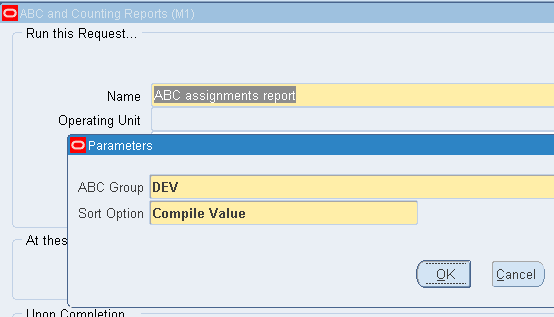

8. Generate ABC Assignment Report

Navigation

Inventory, Vision Operations (USA): Reports > ABC and Counting

- Select ABC and Counting

- Submit a New Request screen will open.

- Select Single Request and press OK.

- ABC and Counting Report form will open.

- Request

- Complete the Parameter form

- ABC Group: Use List of Values to select ABC Assignment Group

- Sort Option: Use the list of Values to select the sort order for the report

- Click Submit button on ABC and Counting Reports.

- Cycle Counting Defining

- Generating Cycle Count Listing

- Entering Actual Quantities

- Approving Adjustment

- Enter a unique name for the cycle count.

- Enter the calendar to use for this cycle count.

- Adjustment Account

Use the list of Values to find the name of report “ABC assignments report”

Press OK button.

CYCLE COUNTING

Cycle Counting consists of:

Cycle Counting Defining

Navigation:

Inventory, Vision Operations (USA): Counting: Cycle Counting>

Cycle Count Select New

This calendar is used to determine the days on which to automatically schedule cycle count.

Enter the Scope and Control information for your cycle count.

- Optionally, enter the date on which the cycle count becomes inactive.

- Late Days: Enter the number of workdays that can pass after the date the count request was generated, before a schedule count becomes a late count.

- Starting Sequence :

- Unscheduled Entries

- Display System Qty

- Maximum

Count Controls

Default to 1.

You may leave this default or enter the number to use as starting

number in the next count request generator. The count sequence number

uniquely identifies a particular count and is used in ordering the cycle

count listing.

Optionally, specify whether you can enter counts for items that are not scheduled to be counted.

Select this field to display system on-hand quantities during count entry.

Automatic Recounts

Select to automatically assign a status of Recount to out of tolerance counts and include them in next cycle counting.

If

you selected automatic recounts, enter the maximum number of times

inventory can generate an automatic recount request. Once this number is

reached the adjustment must be approved or rejected.

Count Subinventories

Defaults to ALL. You may leave this default or select SPECIFIC. If

you choose “Specific” subinventories, you can navigate to the

Subinventory region and select the subinventories to include in the

cycle count.

Select Serial & Schedule Tab. And complete the form.

- Count

- Detail

- Adjustment

- Discrepancy

- Select to automatically schedule this cycle count.

- Frequency: Select “Daily”. This information is used along with the count frequency of each cycle count class, when performing automatic cycle count scheduling. The value you enter here dictates the window of time within which you can enter the count against schedule buckets.

- Count Zero Quantity: Determine whether to automatically generate requests to count items with an on-hand quantity of zero.

- Last Date: Display the last date this cycle count was automatically scheduled.

- Next Date: Leave blank or enter the date of the first workday (Monday) for the next schedule interval when this cycle count is scheduled.

Serial Control Option

Select

the count option to determine whether to exclude serialized items from

the cycle count ( Not Allowed), create one count request for each serial

number ( One per Request ), or create multiple serial details in a

count request ( Multiple per Request ).

Quantity & Serial Numbers: Serial number & quantity are required and are

Validated when entering adjustment.

Quantity Only: Serial number entry is optional if the count quantity

Matches

the system quantity, regardless of whether the serial numbers match. If

you do not enter serial number, the count is marked as completed. And

no adjustments are performed. If you do enter serial numbers, both

quantity and serial numbers are validated when determining whether

adjustments are required.

Adjust

if Possible: If a discrepancy exists between a count quantity & a

system quantity or if the entered serial numbers do not correspond to

the serial number already in the specified location, then the system

will attempt to make adjustment if the adjustment variance & value

are within tolerances. These adjustments consists of receipt & issue

of the appropriate serial numbers to & from the specified location

and are applicable only to instances in which new serial numbers or

shipped serial numbers are counted.

Review All Adjustments: No automatic adjustments are attempted.

Select

the discrepancy option to indicate whether an adjustment is attempted

when a count includes a serial number already assigned to the same item

elsewhere in the system.

If you turn automatic scheduling on, enter the following information

Auto Schedule

Select Adjustment & ABC tab and complete the form.

- Required

- Tolerances

- Qty Variance: Enter the percentage variance of count quantity to

- Adjustment Value: Enter the adjustment values beyond which

- Hit/Miss Analysis: Enter the percentage variance of count quantity

- ABC Initialization ( Optionally)

- Enter the ABC group name on which to base the cycle count item initialization or update.

- Option: Choose one of the following

- None: Do not change to the list of cycle count items.

- (Re)initialize: Use the ABC group you specified to load all

- Update: Use the ABC group you specified to insert new

- Indicate whether to update classes. If an item’s ABC class assignment in the ABC group you specified is different from the cycle count class this item is assigned. The cycle count class is updated for the item with the ABC assignment in the specified ABC group.

- Indicate whether to delete unused item assignment that are no longer referenced in the specified ABC group.

- Re-query the records to ensure the re-initialization has occurred. Wait for Few minutes then select Run from query menu. If the status field does not display “Completed” wait for few more minutes then Run the query again.

- Click on Class button

Approval

Determine when the approval is required for adjustments.

Never: Adjustment transactions are automatically posted where entered Counts differ from system balance.

If Out Of Tolerance:

Adjustment transactions are not automatically posted for the counts

outside a specified approval tolerance. You must approve such adjustment

before posting.

Always: You must approve all cycle count adjustments, regardless of tolerance level before it is posted.

Enter one or more of the following tolerances.

On-hand quantity beyond which adjustments are held for approval.

adjustments are held for approval.

to on-hand quantity beyond which a count entry is considered as a miss for hit/miss reporting.

Items

& their ABC assignments into the list of items to include in your

cycle count. If you already had items defined for your cycle count, this

action deletes existing information & reloads the items from the

ABC group.

cycle count item.

If you choose Update option:

Save your work.

Assign ABC Classes to Cycle Count

Enter ABC classes to include in your cycle count.

- Names of the ABC classes appear in this field. These names were determined in the ABC assignment group.

- Counts per Year: Enter the number of times per year you want to count each item in this class.

- Approval Variance: Optionally, enter positive or negative tolerances. If you do not enter tolerances, a value entered in the cycle count window is used.

- Save your work & close the cycle count classes’ window.

- Click on Item button

Complete the Cycle Count classes form

Cycle Count Items

To define Cycle count Items

- This form displays the cycle count items. You may verify an item’s class & specify an approval variance for specific item

- Save your work & close Cycle Count Item window & Cycle Count window.

- Choose Cycle Count Scheduler from Tools menu.

- Complete cycle count schedule parameter

- Select Include Control Group Items and click OK

Cycle Count Scheduler

- Click the OK button again.

- Select Perform Full Cycle Count from the tools menu.

Perform Full Cycle Count

- Click the OK button again.

- Select Perform Full Cycle Count from the tools menu.

- Parameters

- Use the list of values to enter your cycle count name in the parameters fields next to cycle count listing.

- Click Option button.

- Select Save All Output Files & press OK button.

As we selected frequency as Daily, schedule this program on Daily basis at suitable time.

- Press Submit button on Perform full cycle count screen. Click OK & close all windows.

- Complete ABC and Counting report form.

- Name

- Complete the parameter form.

- Cycle Count Name: Use the list of values to select the name of cycle count.

- Start Date: Defaults to today’s date

- End Date: Defaults to today’s date

- Include Recounts only: Indicate whether to print the listing for recounts only (“Yes”) or all items (“No”)

- Subinventory: Use the list of values to select a specific subinventory to count or leave blank for all subinventories. Suggest to keep it blank

- Display Serial Number

- Click OK button.

- Select the report to automatically run periodically

- Click the Schedule button.

- Select Periodically

Generating Cycle Count Listing

Navigation:

Inventory – Inventory, Vision Operations (USA) : Reports > ABC and Counting, Single Request OK : ABC and Counting Report

Use the list of values to find the name of report, “Cycle Count Listing”

Leave as default value.

Complete the Schedule form.

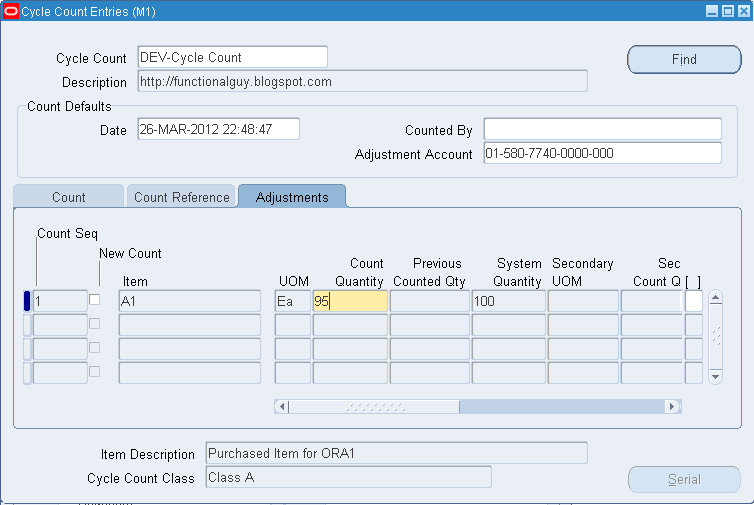

- Query the cycle count to be used.

- To enter scheduled counts.

- Count Quantity

- Save your work and it will get submitted for approval.

- Approver shall take appropriate action and save the response/s .

Entering Actual Quantities

Navigation:

Inventory – Inventory, Vision Operations (USA): Counting > Cycle Counting > Cycle Counting Entries

Enter

the quantity that you counted for each item. Inventory uses this

quantity with the specified unit of measure to determine the value of

cycle count adjustment.

Hi Davendra,

ReplyDeleteI'm using E-Biz 11i. Recently we facing an issue at cycle count. We encounter that the settings of include zero count, does not work well if we did not assign the item into the respective subinventory. This is apart of the setup. The symptom is system do schedule the item with zero quantity to be count, however that item does not appear at the cycle count report. So we always having problem that the count item is less than the actual scheduled.

Therefore now we are working on to assign the item into the subinventory. Not sure this will handle well in R12.

Thanks,

Jasmine

Cycle count is with setup with Max Automatic Recounts as 1.Items are counted using RF devices and WMS control board is being used to assign cycle count tasks to counters . When an item is initially counted and a mismatch is observed b/w system Qty and Counted Qty, recount task is created automatically but it is assigned to the same counter/person who did the initial count and task status remains in Active. This is forcing the same counter to recount the item.

ReplyDeleteCan we setup the application in way that recount task is created in pending status and assigned to none?

very use full Post on Cycle Count..Thank you for the Post.

ReplyDeleteHi,

ReplyDeleteDo you have other document with various scenarios?

Thank you

At this moment we have two cycle counts running 1 for Capital and the other for Non-Capital itema. When I run the Perform Full Cycle Count, the system assigns 15 items each for Capital and Non-Capital Cycle Count.

ReplyDeleteIs there a way that I can increase the number of items from 15 - 25. Is it a setup change ?

Regards,

KR

Hi Kiran,

ReplyDeleteQty of items depend on total number of items in the class and frequency assigned to it. If you want more parts then increase the frequency so than more part will be picked everyday.

Thanks

Devendra